LogiMAT 2026: advasolutions brings adaptive end-to-end automation of intralogistics to life

At LogiMAT 2026, advasolutions showcases a fully automated, AI-powered warehouse solution built for maximum flexibility, scalability, and zero downtime.

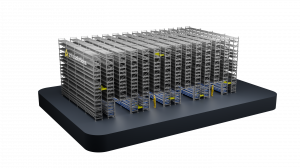

MUNICH, GERMANY, January 13, 2026 /EINPresswire.com/ -- What does a warehouse look like that automatically adapts to any product variety, peak load, and process change—from inbound to outbound, without retooling or operational downtime? At LogiMAT 2026, advasolutions demonstrates exactly that. At booth [Hall 3 / Booth 3C79], visitors will experience a fully automatable end-to-end solution that seamlessly connects goods receipt, storage, picking, and shipping, with speed, flexibility, and scalability at its core. The solution increases the efficiency of fulfillment and logistics processes and provides companies with a future-proof foundation to meet dynamically growing market demands. Additional highlights include new AI-based features such as intelligent quality control and optimized route planning.advasolutions develops automated warehouse systems designed for modularity, scalability, and transparency. By combining innovative hardware with intelligent software, companies can make their logistics processes more flexible, efficient, and competitive. The interaction of autonomous shuttles, an adaptable racking system, and flexibly configurable advaShelves enables the efficient transport, storage, and dynamic movement of items of widely varying sizes, shapes, and packaging types. Instead of using a conventional elevator, vertical movement between levels is handled via the so-called climber—a vertical rack-and-pinion passage that allows the shuttles to change levels using their own drive system. This design results in higher system availability and reduced susceptibility to faults. Scalable both vertically and horizontally, the system optimizes warehouse space utilization and can be seamlessly integrated into existing warehouse structures. The technology is controlled via the advasolutions Warehouse Execution System (WES) and an AI-supported digital twin that visualizes and optimizes warehouse processes and movements in real time, proactively minimizing errors.

Live System Demonstrates Flexibility, Speed, and Variety

At booth [Hall 3 / Booth 3C79], theory becomes practice. Visitors will experience an expanded live system that demonstrates the performance and capabilities of the technology in a tangible way. At the center is the advaShuttle, which moves standard containers, cartons, and individual items flexibly and at high speed. Continuous relocation processes across multiple levels are showcased, highlighting the system’s ability to automatically adapt to a wide variety of items.

Digital Twin Visualizes the End-to-End Process

The live demonstration is complemented by digital insights into the advasolutions WES, which controls all modules, and the associated digital twin. Via monitors and tablets, visitors can follow the complete material flow from inbound to outbound, including live data from a real warehouse. Process states, movements, and utilization levels are visualized. The combination of real-time visualization, physical demonstration, and operational KPIs makes the end-to-end solution transparent and shows what data-driven automation looks like in practice.

AI-Based Enhancements: Quality Control & Optimized Routing

Another highlighted solution being presented at LogiMAT this year is its new AI-based functionalities. Intelligent quality control automatically detects and evaluates process deviations in real time, while optimized, self-learning route planning continuously monitors utilization, availability, and traffic paths within the warehouse to determine the most efficient shuttle routes. The result is fewer errors, shorter cycle times, higher throughput, and reduced energy consumption—tangible benefits that directly impact operating costs and ROI.

advasolutions at LogiMAT

With its trade fair presence, advasolutions addresses both companies planning end-to-end automation projects from a single source and those looking to integrate individual modules into existing systems or customer projects. “At LogiMAT, visitors can experience our technology exactly as it operates in real life—fast, stable, and capable of handling an enormous variety of items. Our customers no longer need to predict which items they will be storing a year from now. The system adapts automatically—whether bottles, cartons, or electronics,” says Dr. Marcus Englert, CEO of advastore SE. “The demonstration also shows how modular and scalable our solution is. Companies can start small, expand step by step, and remain flexible depending on assortment, processes, and growth—without disrupting ongoing operations,” adds Max Dhom, Co-Founder & VP R&D Software at advasolutions.

Booth: Hall 3 / Booth 3C79

Location: LogiMAT 2026, Stuttgart

Date: March 24–26, 2026

Image material available for download here.

Further information: www.advasolutions.com

Off The Beaten Track Communications GmbH

Theresa van den Berg

+49 1517 0274867

advasolutions@otbtcomms.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.